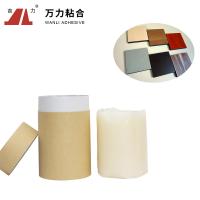

Chinese Factory, Flat Lamination Bonding of Decorative Panels

Reactive PUR Hot Melt Glue WANLI® PUR-1947B with Open Time About 6

Minutes at 25℃ And Perfect Bonding Strength After Curing, Excellent

Moisture & Heat & Chemical Resistance

Wanli® PUR hot melt adhesive PUR-1947B for flat lamination bonding

is a single-component reactive PUR hot melt adhesive with 100%

solid content. PUR-1947B can be used for the bonding of PVC, PETG,

PMMA, PET, melamine impregnated paper and other surface materials

to various wood-based, plastic, metal and other substrates.

Feartured with stable viscosity under heating at a certain

temperature, high initial & final bonding strength, good peel

strength, good heat & humidity & chemical resistance.

APPLICATION

Wanli® PUR hot melt adhesive PUR-1947B is used for flat lamination

bonding. PUR-1947B can be used for the bonding of PVC, PETG, PMMA,

PET, melamine impregnated paper & other surface materials to

various wood-based, plastic, metal & other substrates.

| Application Material | Woodworking Flat Lamination Reactive PUR Hot Melt Adhesives |

| Appearance | Black Solid |

| Component | PUR (Polyurethane) |

| Application Industry | Woodworking Flat Lamination Bonding |

| Solid Content | 100% |

| Operating Temperature | 110~150 ℃( Depend On Machine, Substrate, Environment And Other Conditions) |

| Melt Viscosity | About 5500mPa·s@140℃(Brookfield-ASTMD3236) |

| Open Time | About 6min@25℃ |

| Usage Scope | Flat Lamination Bonding of Various Wood-based, Plastic, Metal etc. |

| Shelf Life | 6 Months |

| Package | 2Kg/Bag, 20Kg/Barrel, 200Kg/Barrel |

FEATURE

Stable viscosity under heating at a certain temperature.

High initial & final bonding strength.

Good peel strength.

Good heat & humidity & chemical resistance.

USER GUIDE

The package of PUR-1947B is suitable for various dispensing

equipment.

The recommended operating temperature is 110~150℃(depends on

substrate, machine, environment and other conditions).

It is better to place finished product in a working environment

with suitable temperature and humidity (recommended temperature:

23~25℃, about 65% relative humidity) to achieve complete curing.

STORAGE

Dry, cool, avoid direct sunlight, no more than 35℃, away from open

fire and heat source.