WUXI WANLI ADHESION MATERIALS CO., LTD.

WUXI WANLI ADHESION MATERIALS CO., LTD. was established in 1995

with a registered capital of 20.91 million yuan. It is located in

Wuxi High-tech Development Zone,Jiangsu Province. It is a

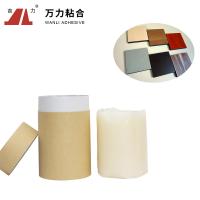

professional manufacturer of PUR hot melt adhesive, two-components

PU adhesive, EVA hot melt adhesive, hot-melt pressure-sensitive

adhesive, polyolefin hot-melt adhesive,functional coating and other

products, providing customers with a complete set of professional

solutions of hot-melt adhesive & coating application.

We adheres to independent innovation and is committed to scientific

research and development. Our products take green environmental

protection as an important standard. And all of our products passed

the China Environmental Labeling Product Certification,

ISO9001-2015, ISO14001-2015, and IATF16949-2016 system

certification.

In order to meet the needs of the market, we established a

wholly-owned subsidiary, Nantong Henghua Adhesive Material

Technology Co., Ltd. in 2010 which is located in Rudong Coastal

Economic Development Zone (exclusive chemica industry park) in

Nantong, Jiangsu Province.

We have excellent technical personnel, capable sales team, perfect

equipment and advanced production technology, with a production

capacity of over 10,000 tons.